Highlights from the Tame The Li-ion: An In-Depth Report on Waste & Recycling Facility Fires in the US/CAN Webinar

The waste and recycling industry faces a number of challenges on a daily basis, one of which being the threat of fires. These fires can spark from hazards such as pressurized tanks, chemicals, hot work activities, fertilizers, cigarette butts and, an emerging culprit, lithium-ion (Li-ion) batteries. While this problem isn’t new, it’s an ongoing issue that can pose further risks to companies’ employees and facilities if fires aren’t detected and managed early.

To help companies in the industry better understand these risks and be prepared for a potential fire event, Ryan Fogelman, JD/MBA, vice president of strategic partnerships for Fire Rover, shared findings from his “4th Annual Reported Waste & Recycling Facility Fires US/CAN” report as well as some solutions to this growing problem during a recent webinar hosted by the National Waste & Recycling Association (NWRA) entitled “Tame The Li-ion: An In-Depth Report on Waste & Recycling Facility Fires in the US/CAN.”

Kicking off the webinar, Fogelman stated that to his surprise, the industry experienced 23 reported fire incidents and seven injuries to firefighters during the first 13 days of April. That is a major change from April 2020 when we were in the midst of the pandemic and some facilities were shut down. In March of this year, the industry incurred 31 reported fire incidents, the second highest March for fire incidents since 2016. As we come out of the pandemic, Fogelman said we will see if 2020 has less fire incidents due to changes in our operations or a slowdown as a result of the pandemic.

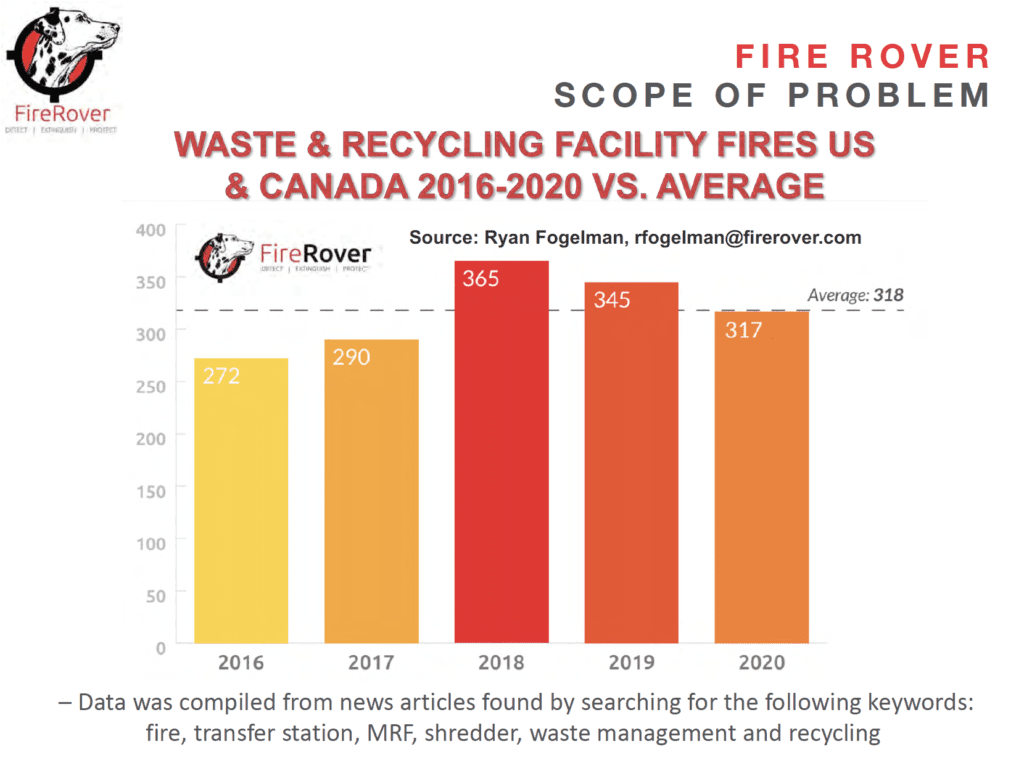

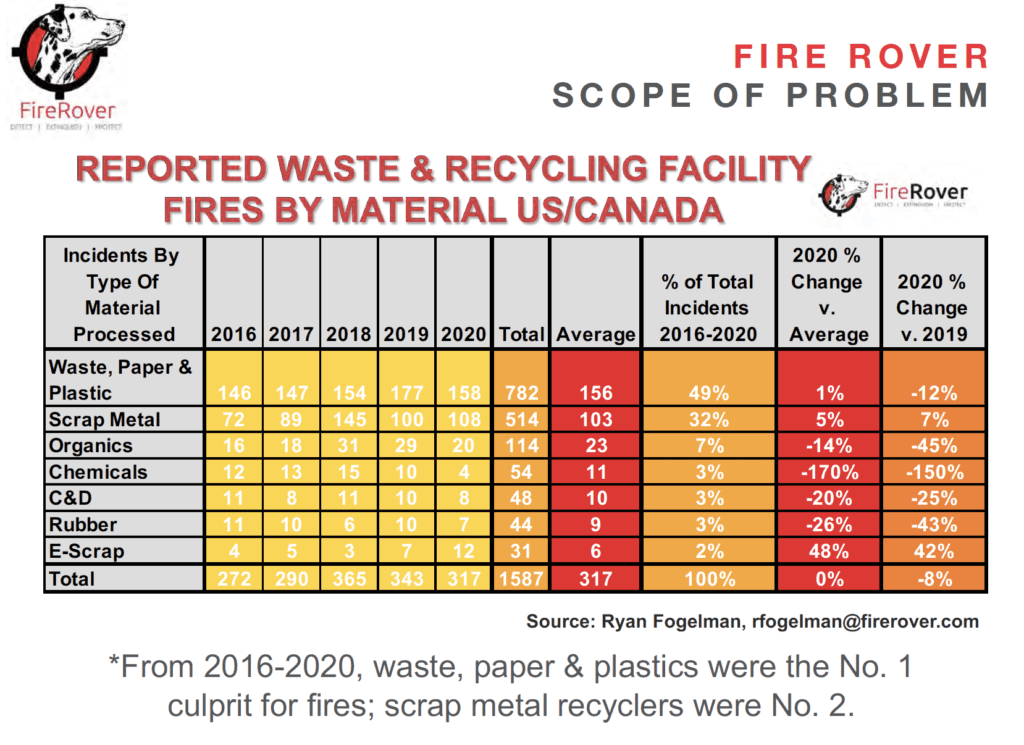

On average, the industry experiences about 318 reported fires per year. In his reports, Fogelman defines “reported” as any fire that has been reported by the media. Typically, those fires are the two-alarm-plus fires that require fire professionals to arrive on scene.

In 2020, waste and recycling facilities in the U.S. and Canada experienced 317 fires, which ranged from small incidents to complete burnouts and occurred in all types of operations including those for metals, rubber, paper, construction and demolition material, plastics, waste, compost, hazardous materials, chemicals and fuels.

While Fogelman’s research focuses on fires within the U.S. and Canada, fires at waste and recycling facilities and in industry vehicles is a global problem.

In the UK, for example, the waste industry faces an estimated 201 waste fires caused by lithium-ion batteries each year, according to a 2021 report entitled “Cutting Lithium-ion Battery Fires in the Waste Industry” published by Eunomia and the Environmental Services Association. Additionally, fires in waste vehicles have increased by 37.5 percent since 2017.

“The global threat [of lithium-ion battery fires] has not gone away; it has gotten worse,” said Fogelman, noting that the industry first saw an uptick of lithium-ion batteries in waste streams in 2018. “The issue is lithium-ion batteries aren’t always easy to spot. If there’s an iPhone, you know the battery is there and that it’s not easily removable. But these batteries can also be hidden in greeting cards, LED balloons, etc., that are placed in the streams and sent to our facilities. Knowing this is a serious problem, we need to remain diligent and focus on fire prevention and risk mitigation from both an operator and insurer perspective.”

Around the time that the industry saw an increase in lithium-ion batteries in waste streams, insurance companies started moving away from the industry. While the industry once had about 50 insurance options, it now has less than 10, according to Nathan Brainard of the Insurance Office of America.

“There are a lot of occupancies that have inherent fire risks in their normal course of business; they just have to have the protections to ensure that they aren’t having significant losses that scare insurance companies,” explained Fogelman. “[When it comes to our industry,] I have personally helped a number of insurance companies understand the risks we face and how following best practices and investing in technologies can help reduce those risks.”

So, how does the industry as a whole make the occupancy more attractive to insurance companies? Fogelman noted two ways: find solutions that allow insurance companies the ability to mitigate their portfolio fire risk and find solutions that allow insurance companies the ability to mitigate waste and recycling facilities’ fire risk.

“It’s not about the number of fires you have; it’s about the severity of the fires,” said Fogelman. “Good operators have less fires than bad operators, but new and innovative solutions are needed when good operators are still having fires.”

While education is important, waste and recycling operators need to invest in proper equipment and technology to reduce the risk of fire incidents. One solution is the Fire Rover, a comprehensive firefighting solution that combats incipient fires and explosions within seconds from ignition. This system is specifically designed for the waste and recycling industry and has successfully responded to more than 1,000 fire events in waste and recycling facilities across the U.S. and Canada since its inception in 2015.

In 2020, Fire Rover took its solution to the next level by adding an additional “quick connect” for fire professionals as part of its Fire Rover Sprinkler Replacement Solution. The quick connect allows fire professionals to take a defensive approach to fighting a lithium-ion battery fire effectively while remaining safely outside the facility, which is increasingly being recommended to fire professionals when they are dealing with battery hazards. The Fire Rover Sprinkler Replacement Solution was developed specifically for lithium-ion battery operations, but it has been applied to materials recovery facilities, transfer stations and scrap metal facilities across the U.S. and Canada.

“We developed this solution with lithium-ion batteries in mind so that the fire professionals wouldn’t have to go inside the facilities and could take a defensive approach to fighting these fires,” explained Fogelman. “We do our best to quickly get our environmentally friendly agent applied to the hazard so we can stop thermal runaway. Once our tank is empty, we can continue to provide targeted application of water for as long as necessary.”

Additionally, Fire Rover has designed and installed a box-less solution for industrial facilities and larger operations like waste-to-energy facilities that utilizes the operators’ existing water infrastructure to replace the sprinkler requirement with an early detection solution that focuses on heat abnormalities and/or the presence of smoke to spot and fight hazards early.

“The one truth that holds true in regard to all fires is that the earlier you identify and fight them, the less harm they cause,” said Fogelman.

Interested in learning more? Listen to a recording of the webinar here.